- References

- Guernsey's supply of green electricity

Key facts

Scope

The project

The old transmission link between Guernsey and Jersey had to be replaced.

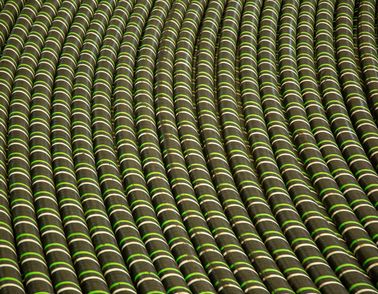

The solution

NKT developed a high-voltage submarine cable system to connect the islands.

We have developed a very collaborative relationship with NKT on this project. This is allowing us to deliver great success in terms of the fast track nature of the project.

— Alan Bates, CEO at Guernsey Electricity

Loading...